Limitronic printers allow perfect compliance with the UNE-53933 regulatory standard with just one printing system. It also has many advantages:

- Tailored design adaptable to each company's facilities.

The printing stations can be adapted to work in a compact, optimised manner in markets, ships or packaging lines. It is thus possible to provide the packaging with all of the required information, such as logos, barcodes, batch, date, etc.

- Print the variable data on each container in real time.

This capability of our printing system clearly solves and streamlines the need to apply unique variable data to each product. For example, each container's weight is displayed on the scale and the time and other necessary data are immediately printed on the EPS box.

- Immediate production control thanks to its connectivity.

Our printing systems are adapted to the demands of a market in which connectivity and immediate data transfer are becoming increasingly necessary in all sectors.

Our printers communicate the data being printed on each pack to other computers and departments regardless of their geolocation. This improves the production control system.

- Perfect, clear and definitive printing.

It efficiently prints text and small-format alphanumeric codes, logos, QR codes and all types of data definitively regardless of temperature and humidity conditions.

- High durability and reliability of our systems.

We guarantee the excellent reliability of our printers, which require little maintenance and can work intensively.

- Time, energy and supply savings.

Each printer installation is designed to increase the productivity of the process. This, together with the printers' speed, provides considerable time savings. In addition, the use of labels is no longer necessary, and ink and energy consumption is reduced by the intelligent metering systems in our machines.

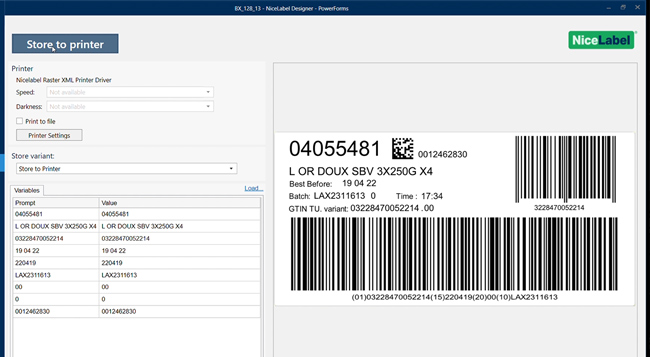

- They can be used with your NiceLabel design software.

You can use your NiceLabel design software with the same interface and ease of use, but with major improvements due to the contributions from our printing system.

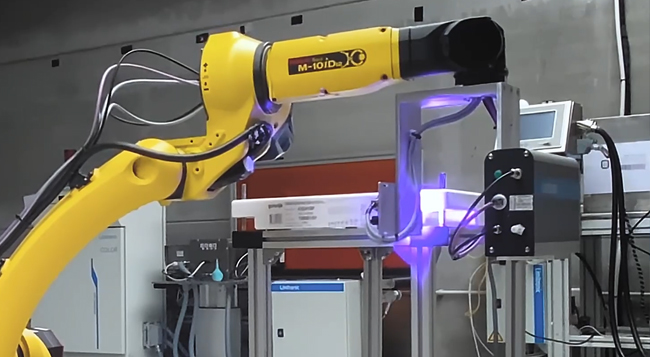

- They can be integrated in collaborative robots.

Our printers can be freely integrated in any kind of automated engineering. Their incorporation in collaborative robots can increase productivity when customising packaging and allow printing on all sides of the boxes with excellent quality.

Do not hesitate to contact Limitronic for more information about our specialized EPS printing systems. Our sales and technical team will be delighted to help you.