Simplification of the purchasing process

Significant reduction of orders and quantities of anonymous boxes compared to multiple and different orders for pre-printed boxes and labels.

Flexibility and freedom

Possibility of immediate and flexible unforeseen production changes and less dependence on the supplier.

In addition, no box becomes obsolete due to changes in legislation or communication, as every print is produced exactly when it is needed.

Advantages in logistics

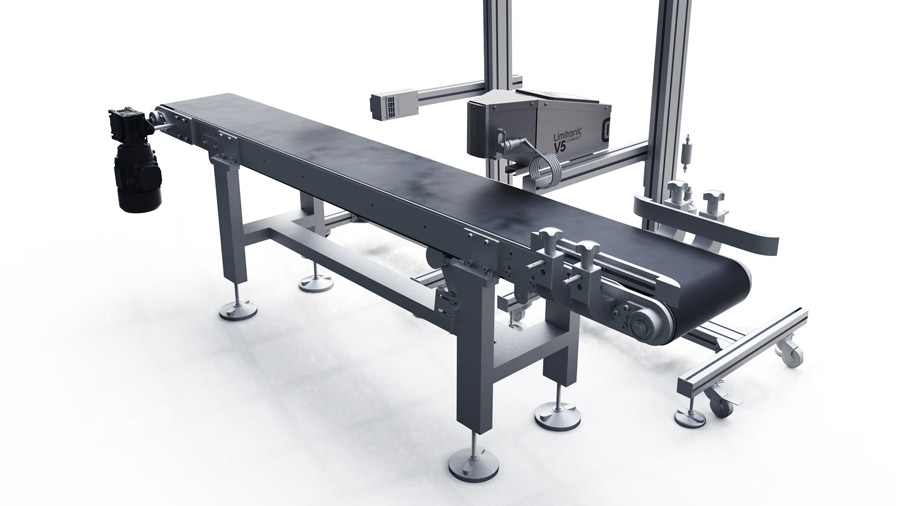

Printing boxes on demand in your own factory gives you independence and self-sufficiency, which translates into agility in shipments, saving space to store box stock.

Greater connectivity

We are part of Industry 4.0. With our system, errors are eliminated, processes are automated and competitiveness is improved.

We can follow the entire process remotely thanks to the connectivity between printers, computers and applications.

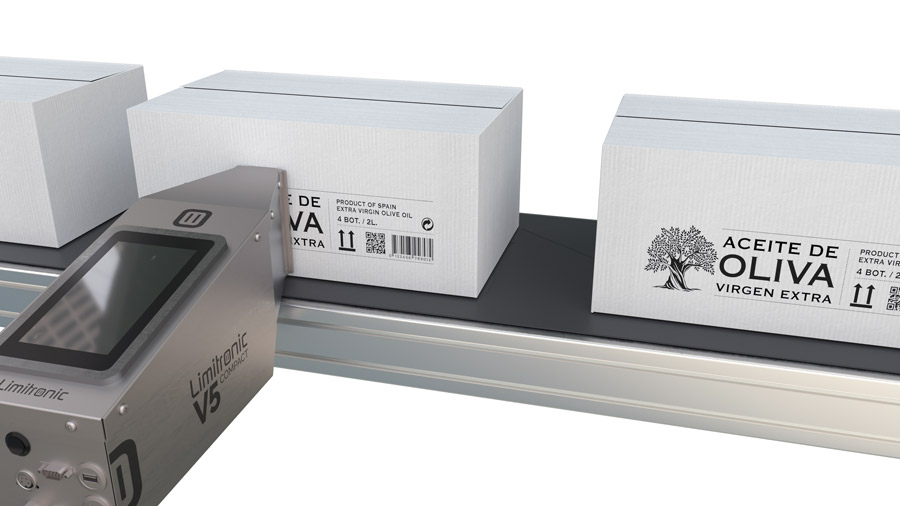

Today's supply chain and logistics have been greatly improved by the evolution of tracking materials and packaged goods. The changing regulations are, together with the safety of food and pharmaceutical products, important drivers for the improvement of traceability programmes. From Limitronic we offer this range of definitive and robust digital printing solutions, perfect for packaging traceability.

All the data of expiry date, origin, location etc. are printed definitively on the containers and packaging of each product.

For more information about our direct printing solutions for porous and non-porous cardboard packaging, please do not hesitate to contact our team, we will be delighted to help you.